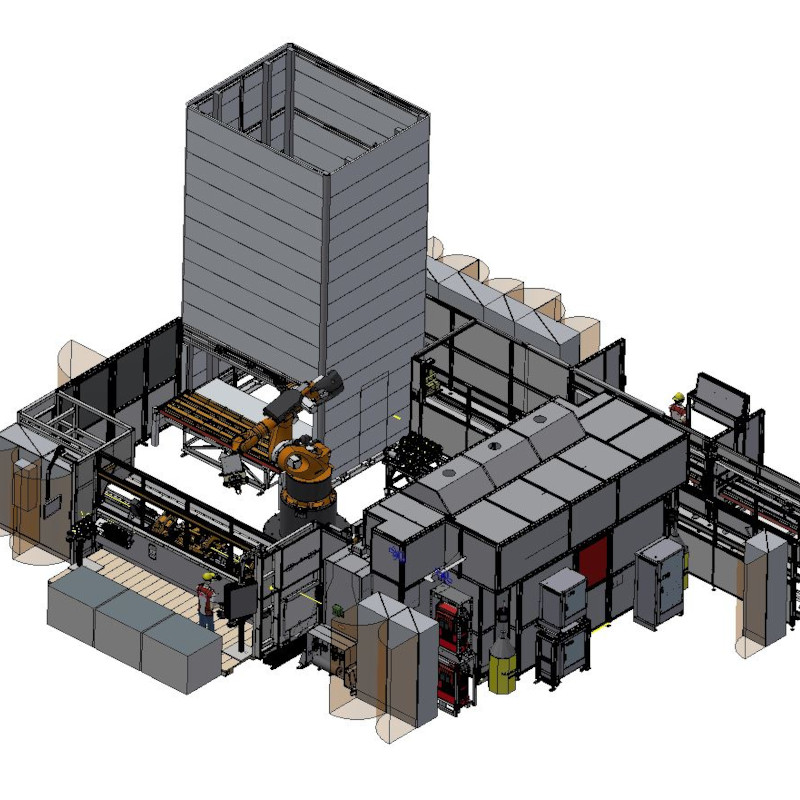

Truck cardan shafts are produced on the GWSA welding machine. The single parts are first inserted into an assembly station and pressed together. The shaft is then picked up by a handling robot and inserted in the welding turner. In the welding station, the seam position is located by means of laser triangulation with 2 robots. The cardan shafts are MAG welded.

The welded component is subsequently provided with a production code in a marking station and then placed into interim storage in a tower storage system. Once the cooling time has passed, the cardan shaft is transferred outwards on 2 different outlet conveyors for further processing.

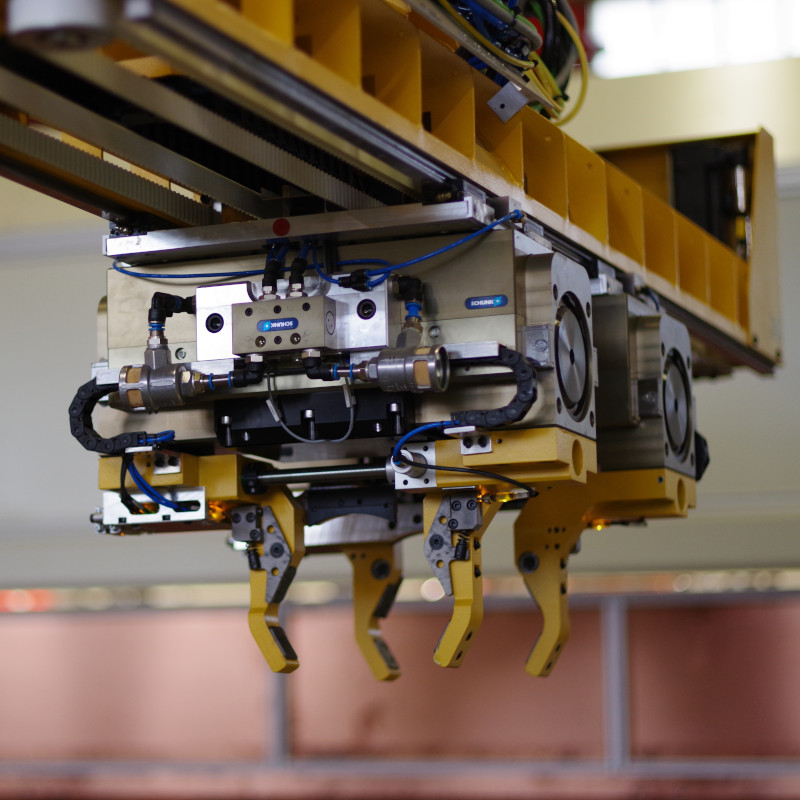

A major challenge was the lot-size-1 productions for a model diversity consisting of several hundred different shafts. This target was achieved by automatic equipping of the welding adapters by means of handling robots.