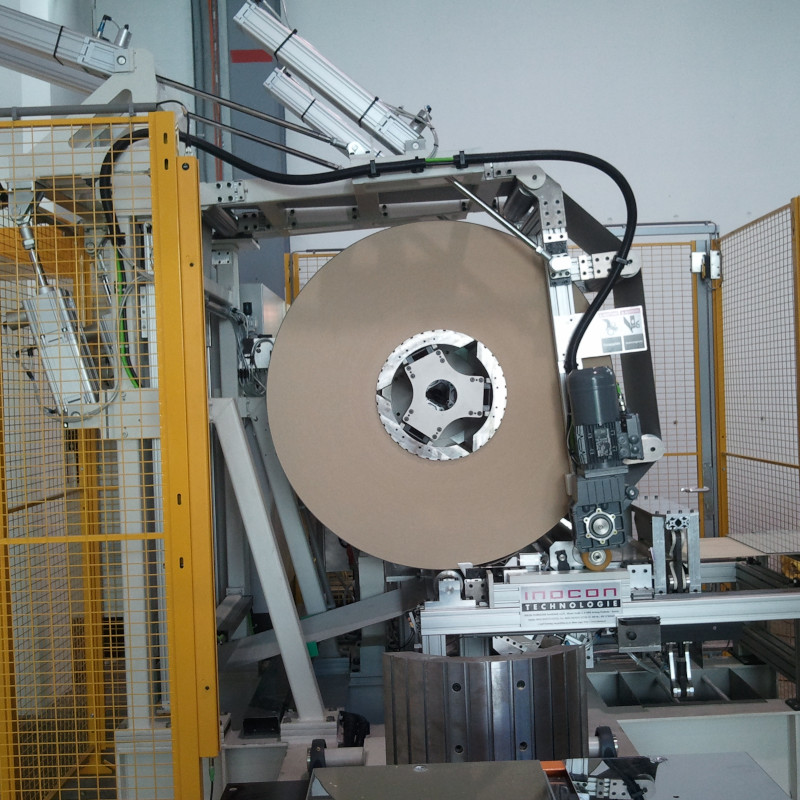

Something that was out of the ordinary for us as well was a batch winder for wooden press boards.

In this case, the boards were sawn to different widths using a multisaw. After the sawing, the segments are supplied to the winder and wound up by a rotary belt system. After the winding, the entire stack is pushed onto a setdown table and rotated through 90°. There, a robot picks up the individual segments.