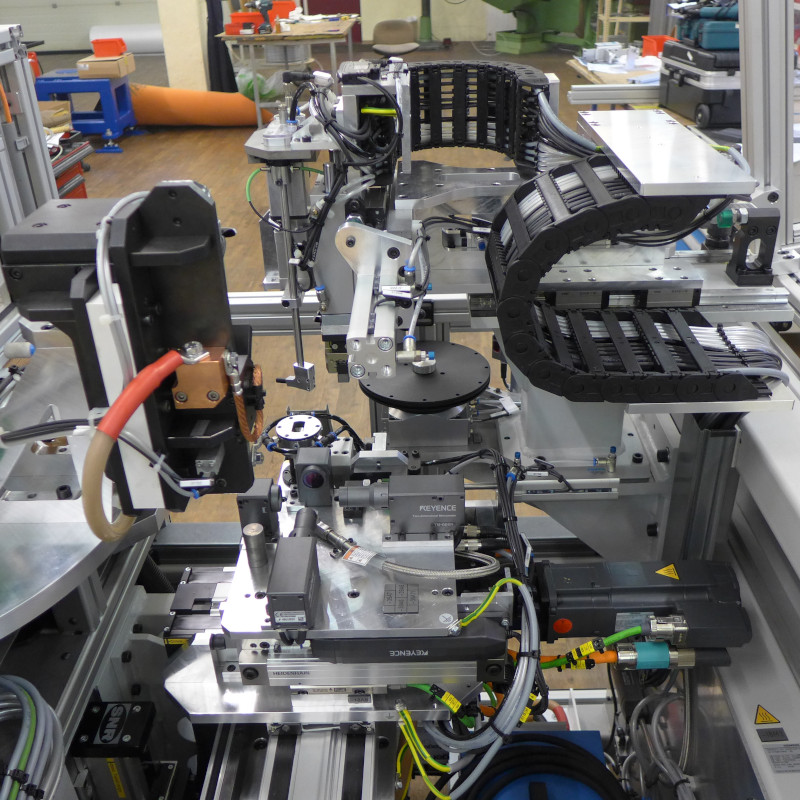

This machine is used to weld ball tips onto the nibs of fountain pens. The system was designed at the request of the customer as a small-scale facility. The nibs are manually clamped in a fixture by the operator. After being clamped, the nib is moved into the system by means of a rotary table so that the ball tip can be added and then welded on. The ball tips are fed fully automatically from a magazine. The nib and ball tip are then aligned in the system and

precisely positioned to within +/-0.02 mm. The ball tip is then joined to the nib made from 24K gold by means of resistance welding. Due to the compactness of the plant, it is easy to move and can be used in a flexible manner.