An entire production line was built for Miele, which manufactures the inner chamber of the steam oven starting from the metal blanks.

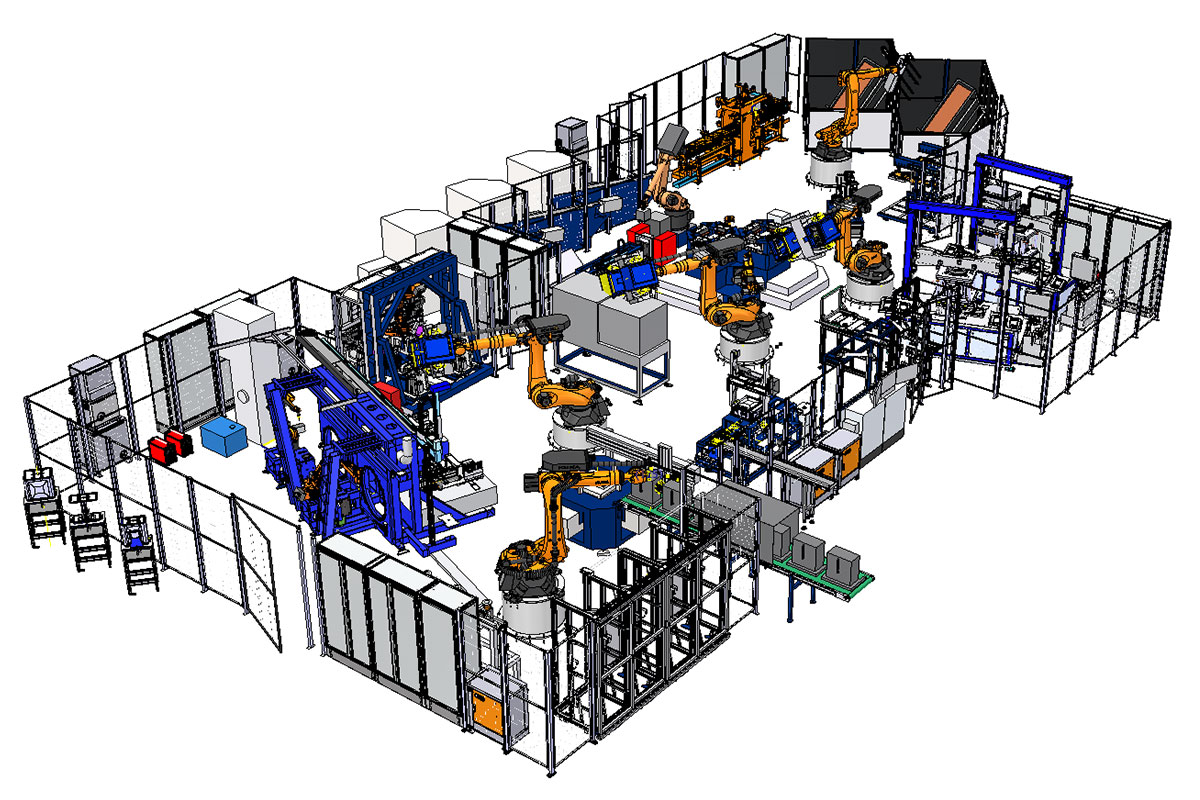

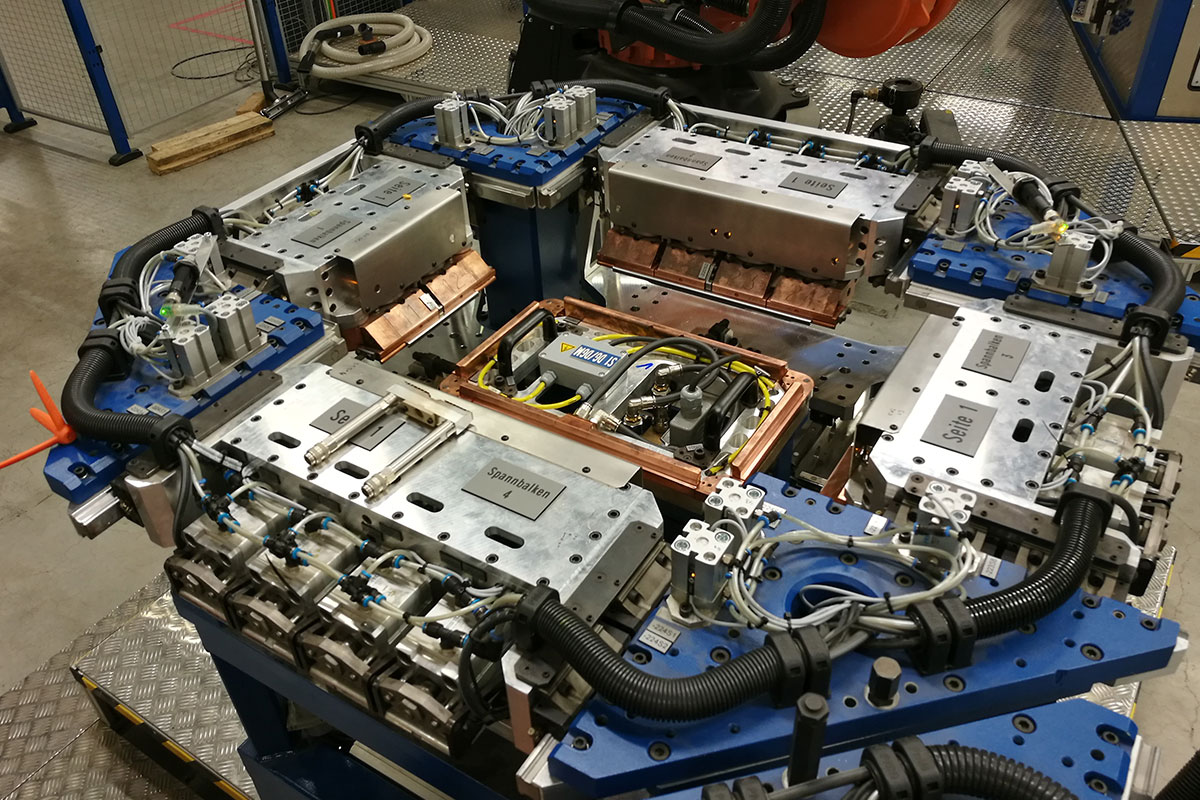

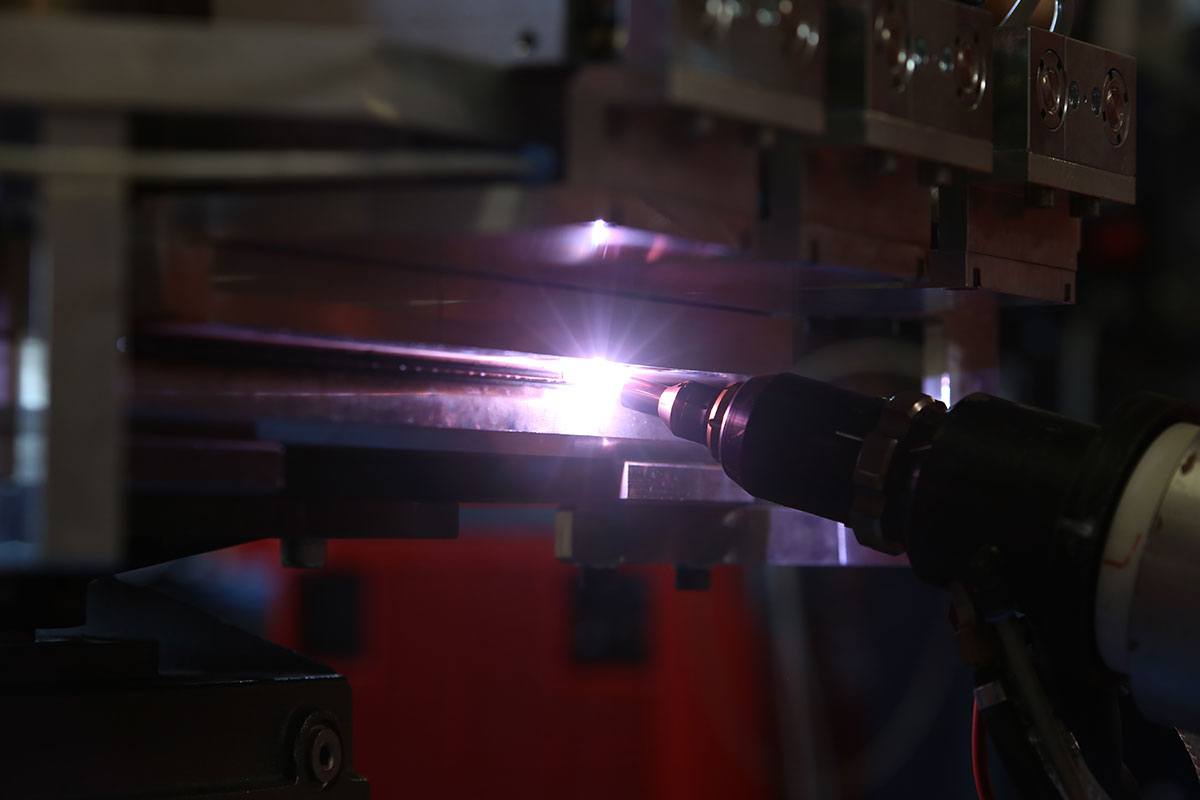

On an area of over 400 m², 11 robots work at 13 processing stations. This starts with the handover of the metal blanks, these are then shaped and further processed. Various welding tasks, such as linear welding the chamber, and welding of all add-on parts are performed using the Plasmatron process. All weld seams are checked by camera.

Additional processes such as bending, crimping and punching are performed on the production line. Thanks to functionally designed double grippers, the cooking chamber is handled completely automatically from the first to the last station on the production line.